All rights reserved © 2015

Bent glass

®

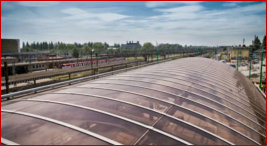

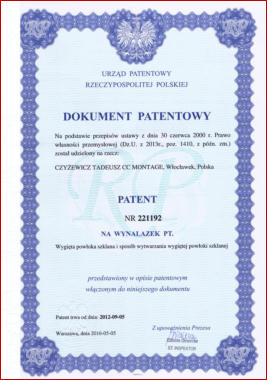

Tempered glass has a mechanical parameters which distinguish it from unhardened glass. In particular, it is five to seven times more resistant to mechanical stress and at the same time is also resilient, meaning that they can be bent to a limited extent by applying the load. To what extent? Good question. It is possible to answer basing on empirical knowledge. Experience shows that the radius at which can be bent toughened safety glass depends on its thickness: the thinner the glass, the more it turns vulnerable to bending. These two features tempered glass - a considerable resistance to mechanical stress and resilience have been used in an innovative project, which is the glass roof over the station Poznań Fast Tram in Poznan. Roofing surface includes 2 740 m2, and is used glass: 55.2 ESG with the test HST. Bending radius glass pane is 7 m. The size of a single pane of glass is 950 × 2 800 mm. The innovative nature of implementation lies in the fact that the contractor has done a coating of flat glass mechanically bent on site. During construction, the contractor dealed with great number of new technical problems. It was necessary to build a device for mechanical bending the glass, it was necessary to design a new profile aluminum hold-down window lengthwise, had finally developed a very effective way of fixing the glass clamping profile steel structures. Technology of the coating was as follows. First, on a steel structure in the interface between two panes of glass welded studs A2 with a diameter of 8 mm. Then, on the ground of bent sheets of glass by means of said device and bent administered in place of the foundation. Aluminum pressure bar had to be thicker than those used in traditional systems mullion-transom: strip width is 100 mm, and support the glass is 35 mm. Additional advantage of mentioned above coating is no transverse pressure on the outside of the windows. In this way, rainwater flow remains unfettered. The transverse sealing two panes is a silicone grout. Glass coating has been designed by Mirosław Filipiak (Profibud company from Poznan), and executed by company CC Montage Tadeusz Czyżewicz (www.ccmontage.com.pl), who reported technical details of construction of the Polish Patent Office (Application No. P. 400658) under the name "bent glass coating and a method for manufacturing a bent glass layer." The described solution we address to architects. It is an interesting way to implement arched roofs, the costs of which are the same as in the case of flat roofs. Special thanks to Sapa Building Sp. o.o for professional support in the design and manufacture of special glass clamping profile. Tadeusz Czyżewicz

Quick contact

CC Montage Ltd. Piaski 9 Street PL 87-800 Włocławek T: +48.542521591 F: +48.542521449 biuro@ccmontage.com.pl Tadeusz Czyżewicz – President tadczyzewicz@ccmontage.com.pl M: +48 601 66 25 04